Type List-Head Protection Equipment

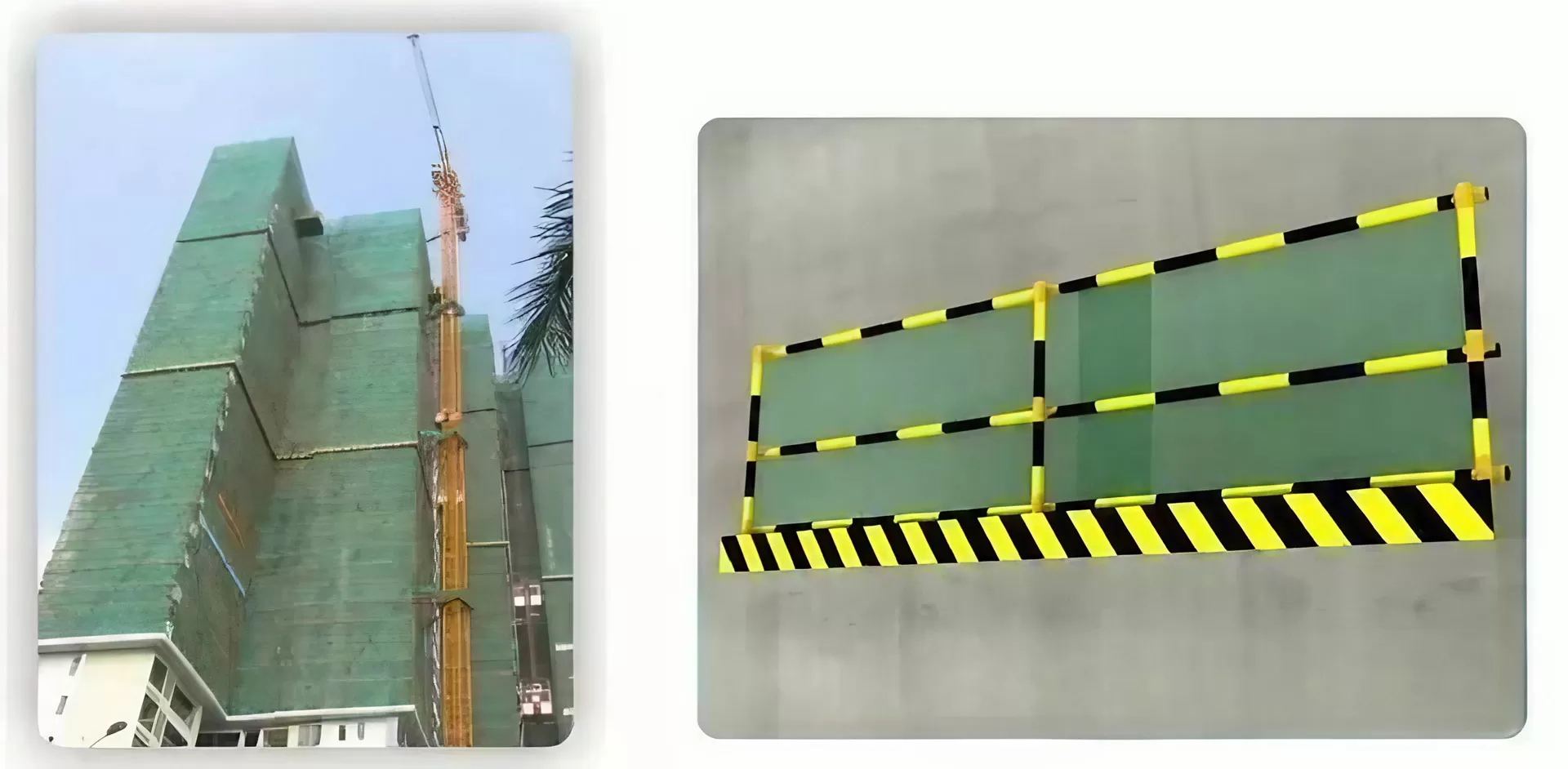

Prevent high-altitude falls and impact injuries to the head

Most Popular

-45%New

Select options

This product has multiple variants. The options may be chosen on the product page

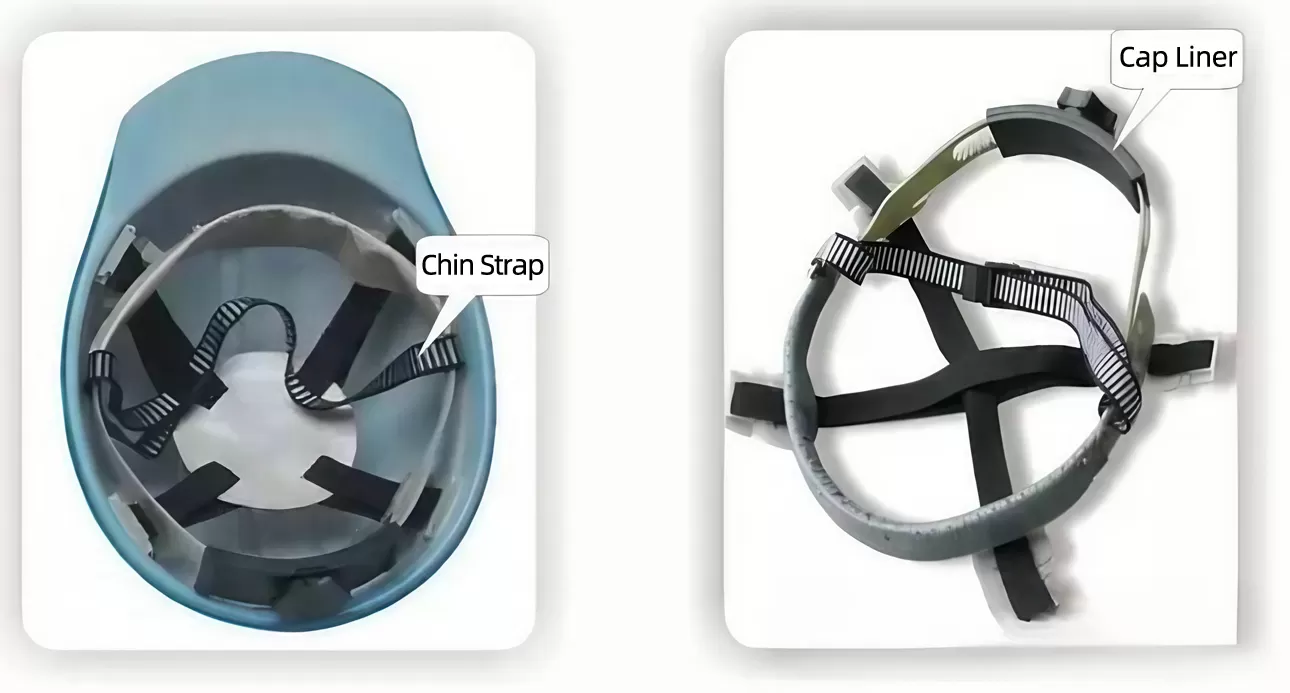

Blue Eagle 6 Points Suspension Hard Hat, Ratchet Cap Style, Electrical Helmet for Safety, Flexible Attachment for Construction, Home and General Head Protection

-30%New

Select options

This product has multiple variants. The options may be chosen on the product page

XYEHS Construction Adjustable Safety Helmet, Hard Hat with Rain Through, Impact Resistant, Half Brim Vented Cap with Premium Imported ABS Shell

XYEHS SR-1032 Safety Baseball Hat Style Bump Cap, Impact Resistant HDPE Shell Insert, EVA Cushion, Lightweight Safety Hard Hat, Reflective Strip, Short Brim, Breathable Hat Comfortable Head Protection Cap

-31%New

Select options

This product has multiple variants. The options may be chosen on the product page

Hard Hat

Hard Hat

Face Shiled

Face Shiled  Safety Glasses

Safety Glasses

Earmuffs

Earmuffs  Earplugs

Earplugs

Rubber Mask

Rubber Mask  Mask

Mask

Work Gloves

Work Gloves

Safety Shoes

Safety Shoes

Reflective Vest

Reflective Vest

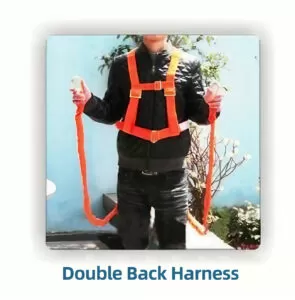

Safety Belt

Safety Belt